Hello everyone, we are a paint factory. We have been in the industry for more than ten years and have witnessed too many coating aspects of steel structure projects. Today I want to talk about something practical - how to calculate the amount of paint and how to control the loss. This is directly related to your project cost and anti-corrosion quality. Buying more is a waste of money, buying less is delaying things. The real skill is to be accurate.

1. The core of calculation: grasp the key point of "Dry Film Thickness"

Paint is not calculated by "jin", but the actual area is purchased by "thickness". What ultimately works is the solid film of paint that firmly adheres to the steel component. Therefore, all calculations must be based on the "target dry film thickness".

There is only one core formula: theoretical dosage = (construction area × dry film thickness) ÷ (solid content × 10)

can't read? Don’t worry, let’s make it “vulgar”:Construction area: It is the total square meters of the steel structure you want to paint.Dry film thickness: How thick you want the paint film to be in the end, measured in microns (μm). This is required by the design, such as 100μm, 150μm.

Solid content: the proportion of active ingredients in the paint that can ultimately form a film. For example, a bucket of paint is marked "50% volume solids", which means that after brushing, half is the effective paint film and the other half is the evaporated solvent.

Manufacturers usually do the conversion well and tell you directly on the instructions: "Theoretical coating rate: when the dry film thickness is 100 μm, X square meters can be painted per liter (ideal surface)." This number is the starting point for your calculations.

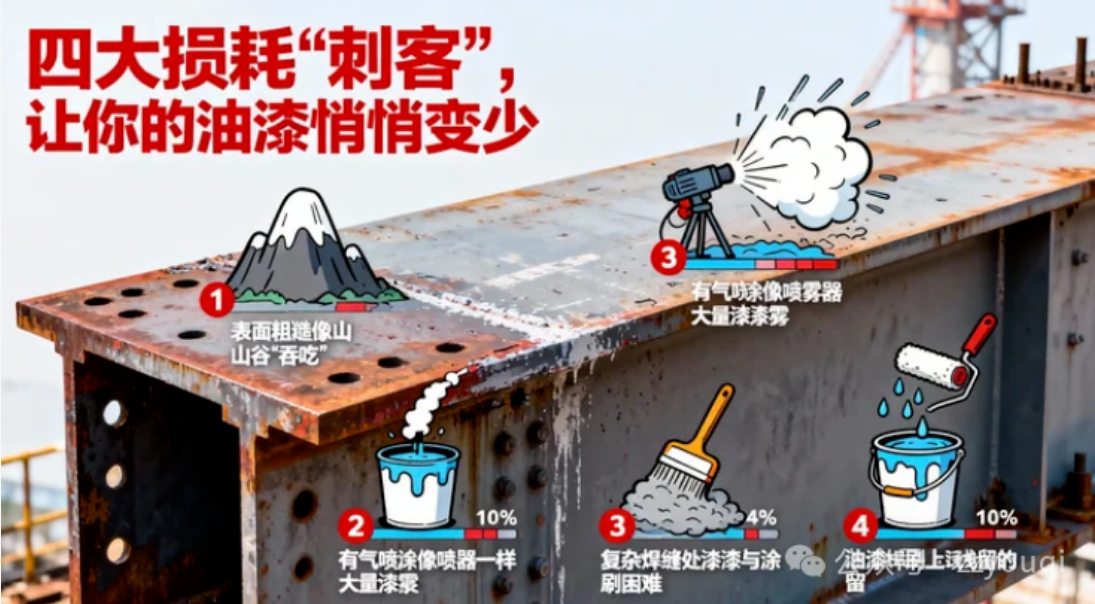

4. 2. The reality is very "skinny": those "loss assassins" who make you buy more paint

5. The theoretical value is very good, but it "shrinks" once construction begins. The actual usage is almost always more than the theoretical value, and the excess is loss. The loss coefficient is usually between 1.5 and 1.8. The key points are as follows:

6. 1. Surface roughness: bumps and bumps are the most “paint-eating”

7. The surface of the steel structure that has just been treated has undulations like sandpaper. In order to ensure that the paint film on the raised areas is also up to standard, more paint will be "hidden" in the depressed areas. The rougher it is handled, the more it is eaten.

8. Shot blasting/sand blasting (fine): Additional loss is about 10-35μm paint thickness.

9. Coarse sandblasting/treatment of old pitting: additional loss may be as high as 60-100μm! It's equivalent to brushing it one more time.

10. 2. Construction method: Choose the right method and save a lot of money

11. Airless spraying: currently the mainstream, with high efficiency and medium loss (about 10%-20%).

12. Air spraying: Atomization is good, but the "flying paint" is serious, half of the paint may float into the air, and the loss exceeds 50%.

13. Roller coating/brush coating: The loss is the lowest (can be less than 5%), suitable for flat surface or touch-up coating, but the efficiency is slow.

14. 3. Components and human factors: complex parts are the difficulty

15. Complex components: It is common to consume more than 30% more paint than flat parts if you want to paint the densely packed welds, angles, and bolted joints evenly and up to standard.

16. Operational proficiency: Novices tend to apply unevenly. If it is too thin, it needs to be repaired. If it is too thick, it will be wasted.

17. Environment: Painting a viaduct outdoors on a windy day? The paint may be blown away before it reaches the wall, and it is not uncommon for the loss to exceed 100%.

18. Bottom of the barrel and tool residue: invisible wasteWhat cannot be scraped off the bucket, what cannot be flushed out of the pipe, what is stuck on the brush... These "sunk costs" can account for an average of 5% of the total usage.

3. Three practical steps: Teach you step by step how to calculate the right purchaseAssume a project: the construction area is 25,000 square meters, the dry film thickness is required to be 100 μm, one of our epoxy paints with a volume solid content of 50% is selected, and airless spraying is planned.

Step 1: Check the theoretical valueThe product instructions indicate: When the dry film is 100μm, the theoretical coating rate is 5㎡/liter.

Step 2: Calculate the theoretical dosageTheoretical dosage = 25000㎡ ÷ 5㎡/liter = 5000 liters.Step 3: Determine the loss and get actualAccording to the on-site assessment: surface shot blasting (loss +), components of moderate complexity (loss +), airless spraying (loss in the middle), weather acceptable (loss -), the comprehensive loss coefficient is 1.5.

Actual purchase quantity = 5000 liters × 1.5 = 7500 liters.Look, it’s 50% more! But this is the amount that is close to reality.

4. Controlling losses means controlling costs: some of our conscientious suggestionsSurface treatment should match: Try to use shot blasting to obtain uniform and moderate roughness. This is the first step to save paint.

The construction methods should be "mixed and matched": use roller coating for large flat surfaces, and brush coating for complex corner welds to reduce the waste of spraying in the entire area.

Be optimistic about the weather before proceeding: Try not to arrange outdoor painting in strong winds, high temperatures, rain or snow. Setting up a temporary protective shed for a large project can save costs in the long run.

Manage tools and buckets well: Use a professional paint bucket with a scraper, and promptly use thinner to recover the remaining paint in the pipes and pumps after construction, which can remove a lot of "remainder".

ConclusionCalculating the amount of paint accurately is not stingy, but scientific management. It is about cost control, but also about the quality of the project - only when the paint film thickness reaches the standard, the anti-corrosion life can be guaranteed. We hope that this guide, which combines our many years of experience, can really help you who are working on the front line of the construction site.

حقوق الطبع والنشر © 2025 Weifang Xingyuan Paint Industry Co., Ltd

خريطة الموقعيستخدم هذا الموقع ملفات تعريف الارتباط لضمان حصولك على أفضل تجربة على موقعنا.

تعليق

(0)