Hello everyone! We are a professional paint manufacturer with many years of experience in paint production and construction. Today, let’s talk about the factors that affect the thickness of the paint film when spraying Fluorocarbon Paint on profiles. Fluorocarbon paint is a coating with excellent comprehensive performance. It can provide excellent anti-corrosion effect when sprayed on the surface of profiles.

However, its anti-corrosion performance depends largely on the thickness of the paint film - if it is too thin, it will easily show the bottom, if it is too thick, it will waste material and affect the appearance. So, what factors are "making trouble"? Below I will give you a brief analysis in vernacular, I hope it will be helpful to you!

1. How to hang materials on profiles: Only when they are hung correctly can the paint film be even.

Before spraying, how to hang the profile is very important. Just like hanging clothes, if they are not hung neatly, some places will not get the sun. The cross-sectional shapes and sizes of profiles are different. If the hanging direction and density are not reasonably selected according to these conditions, the spray gun may be "inadequately taken care of", resulting in uneven or even substandard thickness of the decorative paint film. For example, if profiles with complex cross-sections are hung too densely and the spray gun cannot reach the dead corners, the paint film will be thin and the anti-corrosion effect will be greatly reduced.

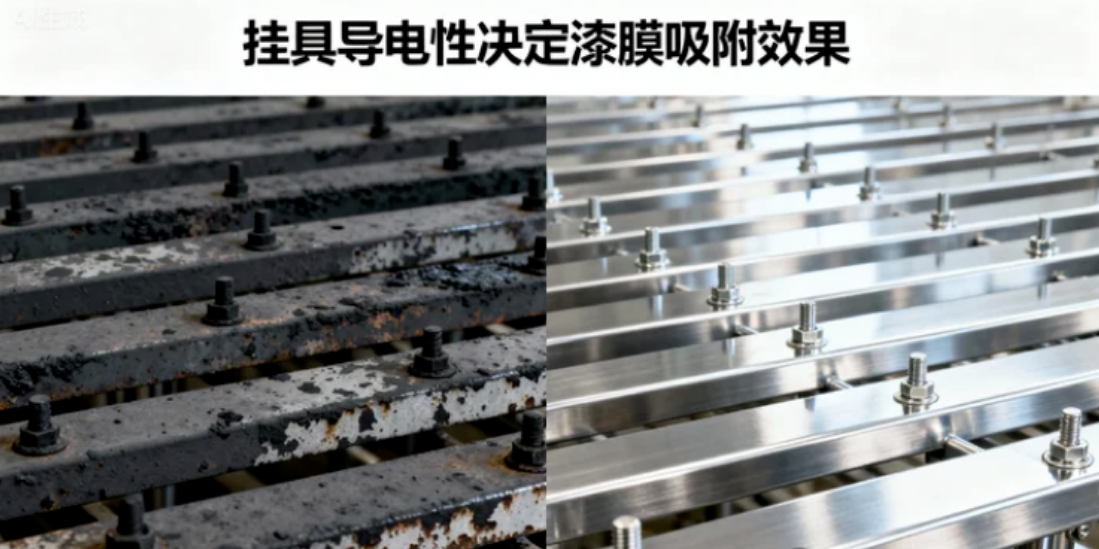

2. The electrical conductivity of the hanging device: If the electrical conductivity is not good, the paint will not stick to it.

After the rack has been used for a long time, a layer of paint film will accumulate on the surface. If not treated, it will be like wearing an "insulating coat" on the rack. If there is poor electrical conductivity between the profile and the hanger, the fluorocarbon paint sprayed from the spray gun will be negatively charged. If there is insufficient positive charge on the profile, the paint mist will not be able to properly adsorb to the surface of the profile. The result? The thickness of the paint film is not up to standard, and even the bottom is exposed, looking speckled. Therefore, it is a key step to clean the hanging fixtures regularly by grinding, beating or burning to maintain smooth conduction.

3. The charge of fluorocarbon paint: the size of the charge determines the "attraction"The charge of fluorocarbon paint is like the magnetic force of a magnet - if the charge is sufficient, the attraction between the paint and the profile will be greater, and the paint mist will be more easily deposited on the profile, forming a thick and uniform paint film. If the charge is reduced and the attractive force is weak, the paint will "float" away and cannot accumulate on the profile, resulting in unqualified film thickness. During production, ensure that the spray gun equipment is normal, adjust the charging parameters, and do not let the power be "lazy".4.

Conveyor chain speed: Speed and paint output must "tacitly cooperate"The conveyor chain is the "conveyor belt" for profiles on the spraying line, and its speed is affected by factors such as curing time and temperature. If the conveyor chain moves too fast and the paint output of the spray gun does not keep up, the paint film may be too thin; conversely, if it is too slow, it may be too thick. This requires adjusting the speed of the conveyor chain and the amount of paint produced by the spray gun just like adjusting the rhythm of music. For example, when the speed is fixed, appropriately adjusting the paint output can ensure that the paint film thickness reaches the standard and avoid waste.

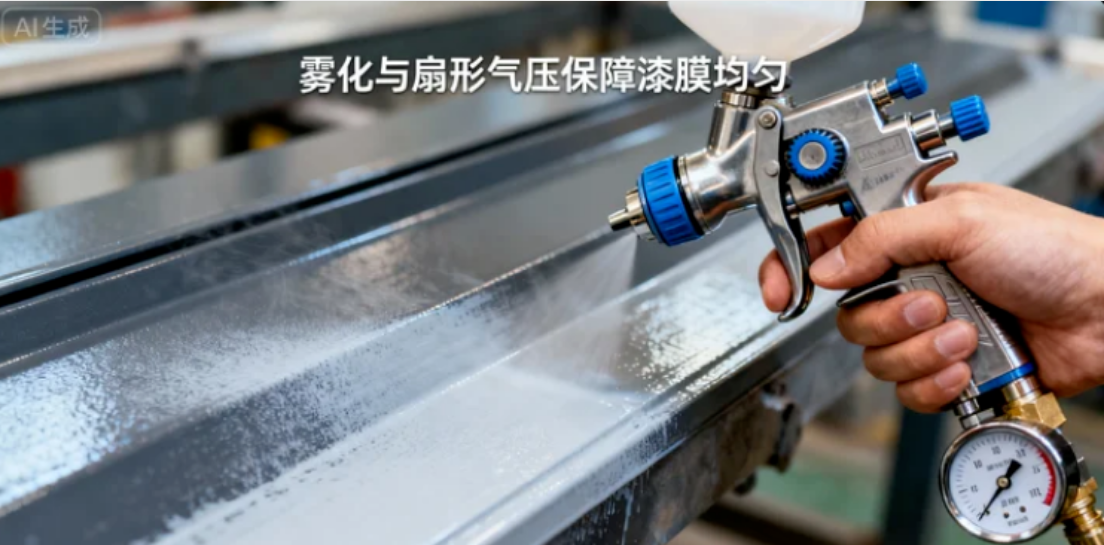

5. Atomization air pressure and fan air pressure of spray paint: Only when the pressure is adjusted well can the paint mist be "obedient"

The atomization air pressure determines how finely the fluorocarbon paint is sprayed out - if the air pressure is too small, the paint mist will be thick and unevenly distributed; if the air pressure is too high, it may be over-atomized and waste material. The fan-shaped air pressure controls the width of the paint mist coverage, just like the size of the fan opening. These two pressures must be coordinated with the conveyor chain speed and spray gun distance, otherwise the problem of uneven paint film thickness will easily occur. Simply put, after adjusting the pressure, the paint mist can be evenly "spread" on the profile, and the visual effect will be more beautiful.

حقوق الطبع والنشر © 2025 Weifang Xingyuan Paint Industry Co., Ltd

خريطة الموقعيستخدم هذا الموقع ملفات تعريف الارتباط لضمان حصولك على أفضل تجربة على موقعنا.

تعليق

(0)