Want to withstand all the wind and rain with just one coat of primer?Don’t wait until your equipment gets rusty before you regret not listening!

Today, I will use the most popular vernacular to tell you clearly: Epoxy zinc-rich primer, why is it strictly not recommended to let it "streaking" for work.

1. Role positioning: Epoxy zinc-rich primer is an “anti-corrosion pioneer” rather than an “all-round warrior”

Let’s first figure out what exactly epoxy zinc-rich primer does.Imagine you have to protect a piece of steel from corrosion, like sending an army.

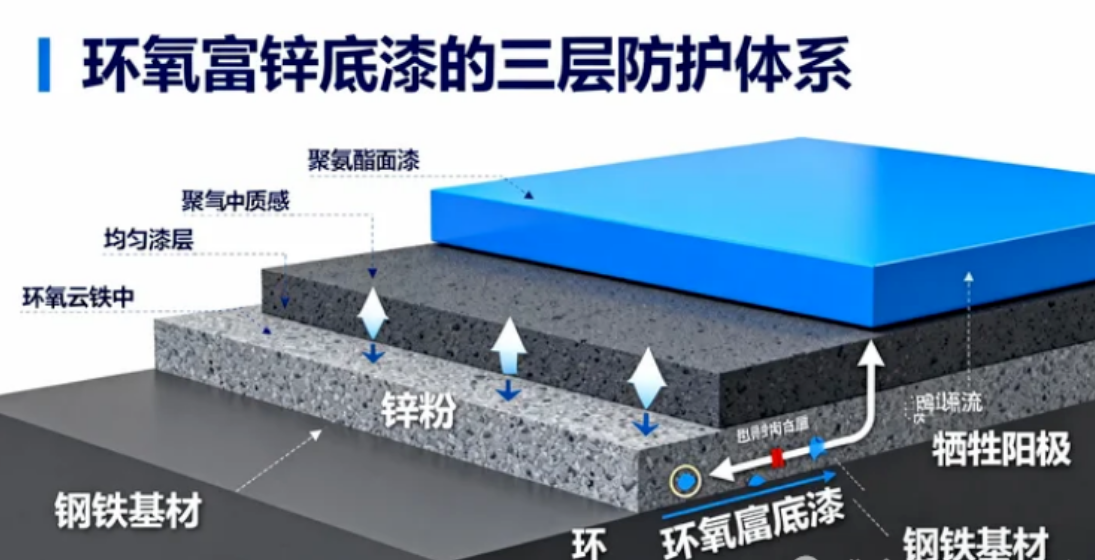

Epoxy zinc-rich primer is the "vanguard death squad" in this army.It contains a large amount of zinc powder. The chemical activity of zinc is higher than that of iron. When corrosive media (such as moisture and salt) attack, zinc will "sacrifice" itself and react with corrosive substances preferentially, thus protecting the underlying steel base material.

This process is called "Sacrificial Anode Protection" and is its core and most irreplaceable value.But after all, it is just a "vanguard". It can take the lead and make sacrifices, but it is not good at defense and cannot fight for a long time.To truly build a long-term anti-corrosion system, it needs to be equipped with professional "center coat" and "defender" - that is, intermediate paint and top coat.

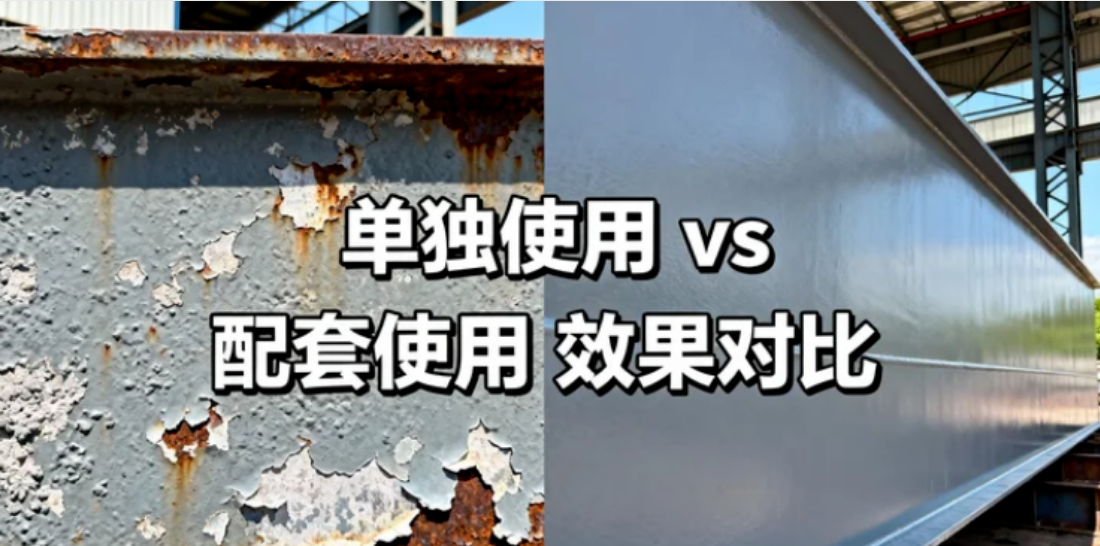

2 Four major shortcomings, the cost of "streaking" is far beyond your imaginationWhy can't this "pioneer" face all the storms alone?Take a look at its four major shortcomings when used alone, and you will understand.

First, I am afraid of the sun, which will cause it to "powder" after being exposed to the sun for a long time.

Epoxy resin has a fatal weakness - it is afraid of ultraviolet rays.After being exposed to the sun for a long time, the coating will gradually age and powder, and the surface will turn into a layer of loose powder.The anti-corrosion performance of a coating that loses its integrity plummets.

Just like human skin that is exposed to the sun for a long time without applying sunscreen will peel and age.

Second, the zinc powder is consumed quickly and the "hero" dies young.Without the sealing protection of topcoat, zinc powder is directly exposed to the air, wind and rain, which will accelerate its consumption.It could be "sacrificed" to protect steel for 10 years, but it may be exhausted in 3-5 years, greatly shortening the overall anti-corrosion life.

This is equivalent to letting your "Suicide Squad" be consumed prematurely without cover, and the gain outweighs the loss.

Third, he looks ugly and rough.After the epoxy zinc-rich primer is cured, the surface is usually gray or dark gray and rough.For many occasions with aesthetic requirements, such as factory exterior walls, stadium steel structures, municipal facilities, etc., such an appearance is completely unqualified.

Fourth, calculating the general ledger is actually more expensive.On the surface, only one coat of paint saves materials and labor.But the reality is that if the coating fails prematurely, you will need to carry out extensive repairs or even repaint the entire area within 3-5 years.

During this period, the downtime losses, rust removal and polishing costs, and secondary construction costs add up to much more than the original cost of complete matching painting at one time.If you are greedy for small gains, you will often suffer big losses.

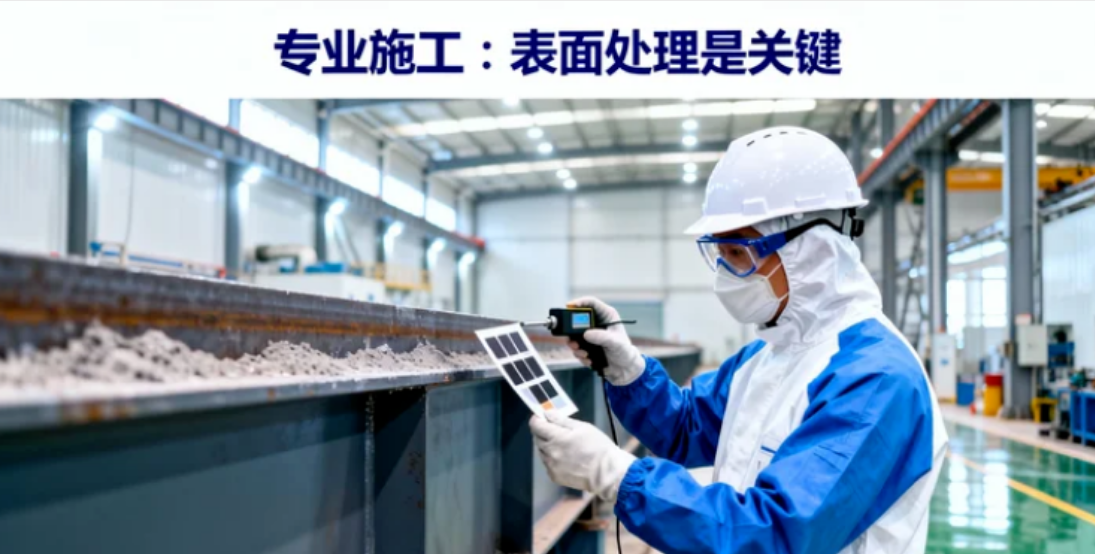

3 Correct usage, a good horse with a good saddle can "serve" longerSo, epoxy zinc-rich primer

حقوق الطبع والنشر © 2025 Weifang Xingyuan Paint Industry Co., Ltd

خريطة الموقعيستخدم هذا الموقع ملفات تعريف الارتباط لضمان حصولك على أفضل تجربة على موقعنا.

تعليق

(0)